The Duluth Aviation Institute is building their own replica of “The Lark of Duluth” which was the genesis of the Benoist Type XIV that we are replicating for the Benoist 2014 project, so we are comparing notes and swapping information with them as both projects progress. Their first flight will be about six months before ours, so we thought it would be good to drop in on them and check on their progress as 2012 draws to a close.

The Benoist project we’re building to recreate the 100th anniversary of the first scheduled airplane airline flight by Tony Jannus uses a six-cylinder two-cycle 75hp Roberts engine.

We know of only seven in the world and there are none to be purchased. This is one of two 4-cylinder 50hp Roberts engines I found and acquired.

We were able to borrow a six-cylinder engine from Old Rhinebeck Aerodrome that Cole Palen had acquired years ago to reverse-engineer. It had been in a crash and the case had been welded in several places.

Here’s a view of the back end with the gears for the single magneto, water pump and rotary valve induction tube.

The 75hp six-cylinder engine has two more cylinders (12 ½ hp per cylinder) than the 50hp four-cylinder and uses two of the same carburetors.

Here’s a rough cylinder liner casting on the left. The one on the right has been machined and the top partially cut out to check for proper thickness. It was actually too thin in one spot and the casting pattern had to be adjusted to compensate. Any bad parts and pieces can be melted back into the pot and used in a future attempt.

Here are steps from left to right in casting and machining the cast iron pistons.

Here are six connecting rods for one engine. The big end connects to the crankshaft with two bolts and another curved piece and the little end connects to a piston with a piston pin. Each assembly will go up and down in the cast iron cylinder liner twenty times a second!.

Here are lower crankcase halves. They were easier to make than the upper halves and were made first. The one on the right is from the borrowed original engine and the one on the left is newly made. The square tab at the lower left of each is where the magneto bolts on.

Here, the crankshaft is set up on a lathe for final machining. This started life as a 900 lb. solid billet. After much whittling down, and two sessions of annealing, it will end up weighing about 48 lbs.!

So what do you think of the progress so far?!

For about a year now I have been working with an archivist I hired to try and organize all the stuff I’ve saved over the years including; pictures, trophies, artifacts, clothing, etc.

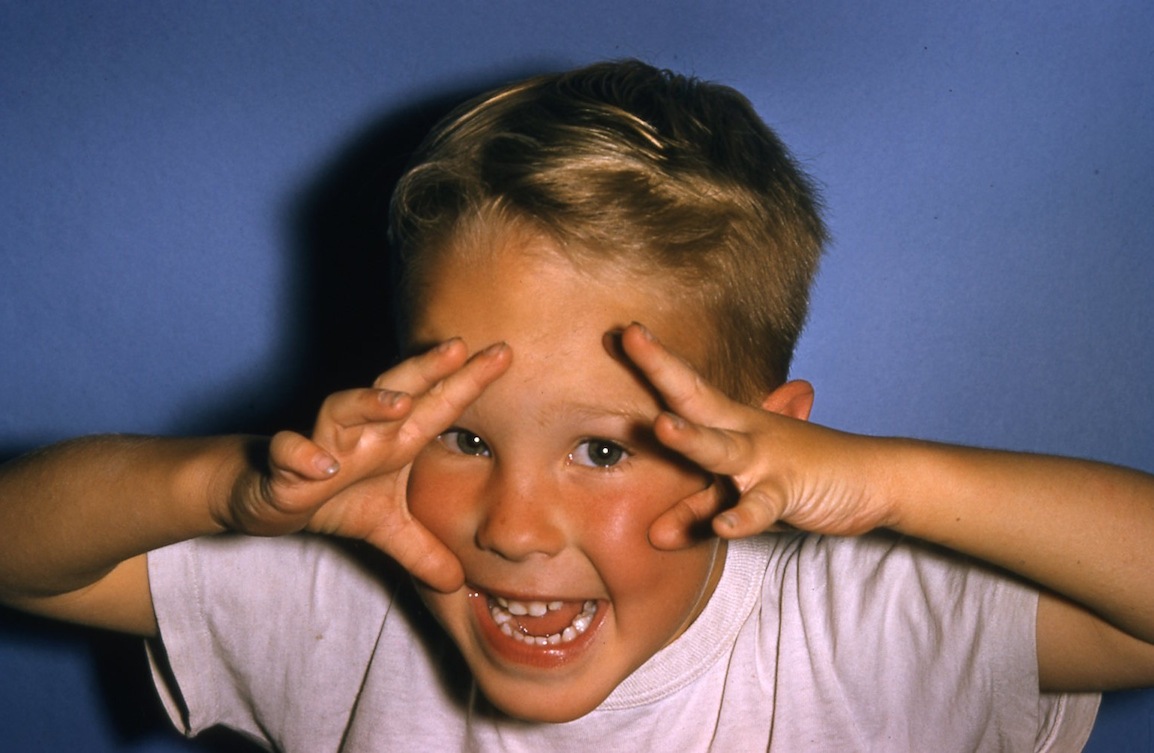

One of the great finds were in slides my father had taken when I was a little kid that I had NEVER seen before. He was an amateur photographer and passed away in 2006. My mother was always worried about what to do with all the slides that he took . . . about 100,000 of them!

Since I now had an archivist on staff, I stepped up to the plate for the family and brought everything up from Miami to Fantasy of Flight. My car was totally loaded with every seat packed to the ceiling.

My Suburban loaded down with my Dad’s slides! The picture is of his mother who used to entertain the troops singing and dancing in WWI like Bob Hope did in WWII.

My dad took a lot of nature photography, animals, and artistic scenes and made a calendar for many years with his best pics. I knew there would be a lot of those types of pictures but was hoping for some family shots as well. I was not to be disappointed!

Here’s a shot of me as a baby. I had never seen picture until now!

There were a good number of other great shots that I had never seen before of me and my family.

Here, a young Kermit plays Peek a Boo for Dad the Cameraman!

Recently, we brought everything I had saved from everywhere to one spot and began the process of trying to organize things in some fashion. I can’t believe all that I’ve collected over the years and now realize I will need more space to properly store it. It’s amazing how seeing items can bring back a flood of memories.

I will continue to collect stuff for my personal archives as well as for Fantasy of Flight and am beginning to think there will always be job security for my archivist!

Kermit

People are starting to take notice of our project to recreate the world’s first schedule airline service on January 1, 2014. Local Tampa Fox News affiliate WTVT recently aired a segment on the Benoist project featuring our fearless leader, Kermit Weeks.

Are you making plans to be there when we fly?

Recently, Kermit and the crew visited Duluth, MN to check up on the progress of the “Lark of Duluth” project being built by the Duluth Aviation Institute.

This Benoist is a replica of the forerunner of the Benoist we’re building for the 100th Anniversary flight of the first scheduled airplane airline service on January 1st, 2014 flown by Tony Jannus from St. Pete to Tampa. While we are approaching our construction efforts and purposes from two different design perspectives, our project gets to benefit somewhat by theirs, as we’re not “on stage” until six months after they are.

The Engine

Since there are no original 75hp six-cylinder 2-cycle Roberts engine available for our Benoist, we’re building one from scratch. They have opted to use an off-the-shelf 140hp 4-cylinder 4-cycle GM marine engine. Both are liquid cooled.

Since their engine turns at a higher rpm, they will have to change their sprocket ratio from the engine to the propeller to get the propeller to turn at the proper rpm. Our sprocket ratio will be the original 1:1, meaning the propeller will be turning the same rpm as the engine.

While it will certainly be less costly than our engine, it will NOT sound like ours. Think Honda vs. Harley!

The Cockpit

Here’s their cockpit. Kermit loved the way they did their seat construction. Currently, ours is plywood.

We’re sure the original did NOT have seat belts but both projects use them for safety.

The main control stick is the tall one and the rudder control is the handle on the left… forward for right and backward for left. Their workmanship is awesome!

The Wings

Here are their finished wings!

They hope to fly their airplane for many summer seasons so opted to paint all the fabric surfaces.

Most of the original pictures show unpainted fabric surfaces, which we will reproduce with just clear dope.

Showing off the Prop

Here, project head Mark Marino and Kermit show the position of the propeller, which is driven by two sprockets and a large chain.

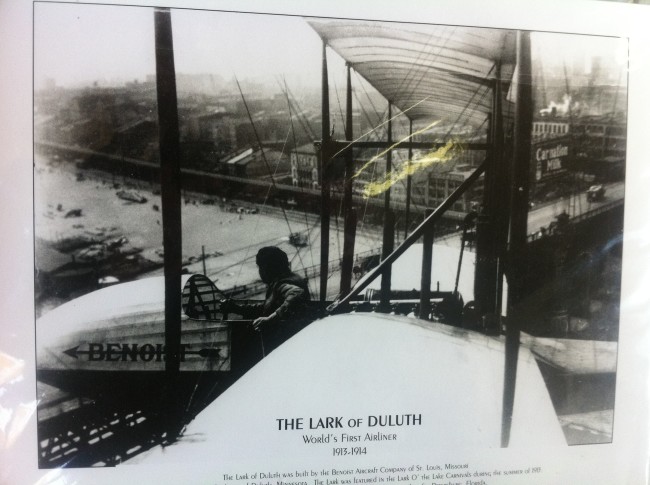

This picture below was taken from the original airplane over Duluth from a camera mounted out on the wing. You can see the pilot squeezing the bulb with his left hand to take the picture!

Our visit pointed out just how far we have to go but at the same time served as a source of inspiration for all involved!